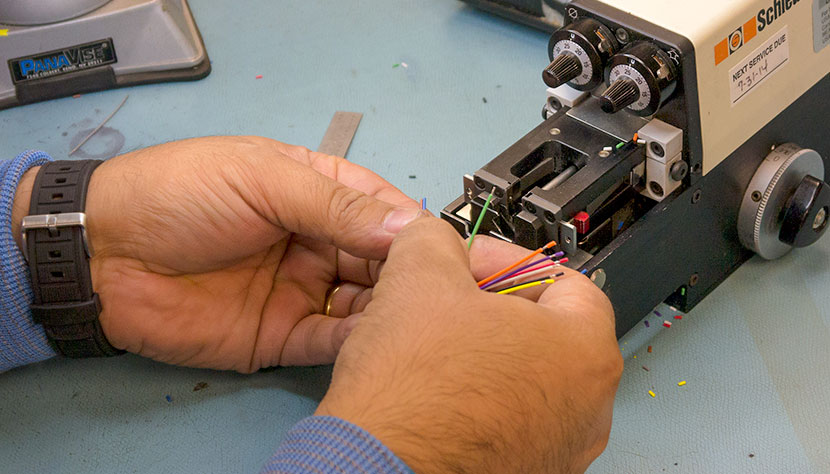

A main stay of our company since its inception over a decade ago has been to manufacture high reliability, complex cables and harnesses.

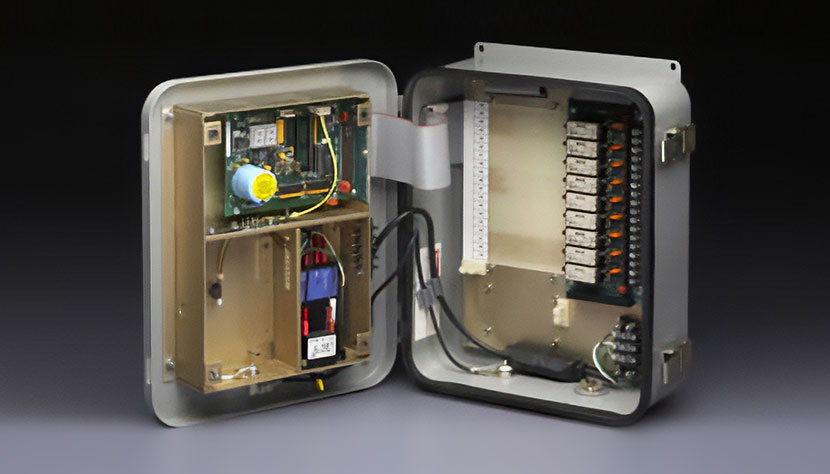

4FRONT's customer focused integration services include subassembly, complete box/system level build, custom packaging and direct order fulfillment. Our strategic location, lean expertise, experienced workforce, and competitive rates gives our customers a strategic advantage.